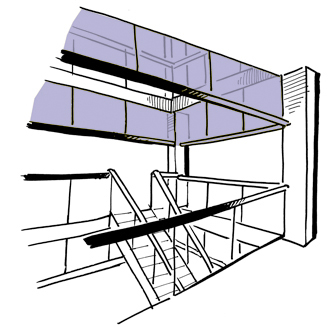

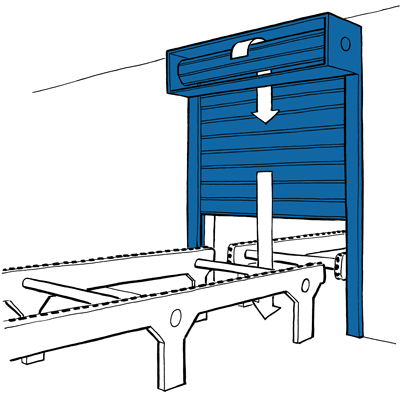

A fire curtain is used where, if there is a fire, it is necessary to create a temporary barrier within an opening which seals off the area on fire. The curtain descends and prevents any fire and smoke from spreading from one area to another. It also allows people access to protected escape routes without any loss of fire resistance.

They provide 180 minutes of continuous fire containment with a standard drop down system. Each curtain is suspended on a single barrel up to 6 metres wide and 8 metres high. Overlapping curtains are used to protect larger areas, please see our architect’s page for more information on our multi-barrelled fire curtain systems.

High and certified performance – FOGO fire curtains have been tested as fire barriers for either 60, 120 or 180 minutes resistance, in accordance with EN 1634-1. They have E60-C, E120-C and E180-C ratings in accordance with EN 13501-2, thereby achieving an integrity rating for either 60, 120 or 180 minutes.

Another versions if our fire curtains have class EW 120 in accordance with EN 13501-2, what demonstrates that the fabric re-radiates only a limited amount of heat.

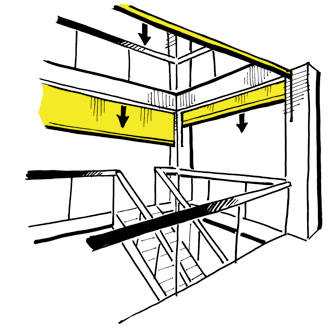

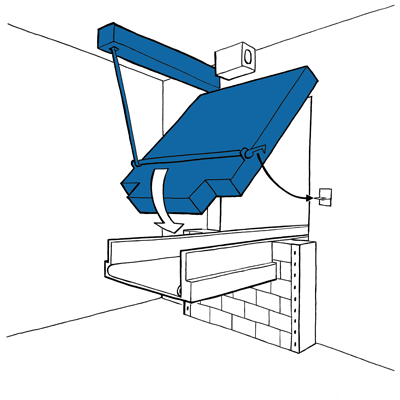

No power needed to operate it – FOGO fire curtain unwinds to its operational position under the influence of gravity in a “gravity fail-safe” manner without the need for power.

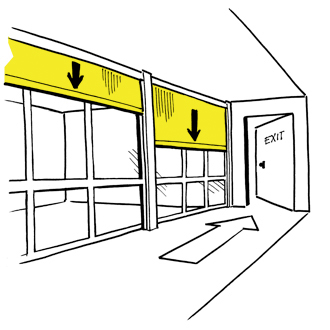

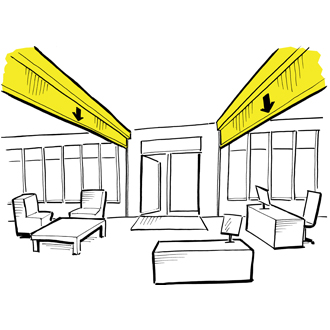

Compact and low in weight – FOGO fire curtain is lightweight and compact, which enables it to be installed easily in a place with space constraints such as a false ceiling. Such a roller fire curtain is much more unobtrusive than a roller shutter with a comparable performance.

Virtually invisible when rolled up – There are no visible fixings either on the underside of the headbox or on the bottom bars. The headbox, the bottom bar and the side guides can be powder-coated to a RAL colour to blend in with the building.

A wide range of options – FOGO fire curtain can easily be adapted to the physical constraints of the building. All system components – headboxes, fabric, bottom bars, drive systems – can be customised to your needs. See our options tab and leaflet for further information.